Sustainability at Norrøna: in defence of radical transparency

Will Ross, June 9, 2017

When exploring prime backcountry in the winter, one key indicator you can use to get a feel for the terrain is to take note of how many flashes of bright checkered ski suits pass by your route. Highly recognisable and now iconic, the colourways from Norway’s Norrøna are distinguished and can often be found seeking out some of the best winter backcountry out there.

In apparel, most brands have come onboard to the fact that producing durable gear with a minimal impact on the planet is probably good business. One approach to incentivising brands is to measure their progress using the the same scale, according to a common set of criteria. You could also argue that bespoke measuring systems provide a surerior path to progress, especially when considering the social impact of production chains that can vary greatly (local v. remote).

This is especially true for brands that defy trends in design, production and distribution. In the case of Norrøna, a clear checklist is hosted on their website, itemizing CSR goals in the lead up to 2020. For them, it’s always been a given that products should be highly durable – their Scandinavian origin suggests this much. Working beyond this principle to reduce impact in their first place is their leading edge.

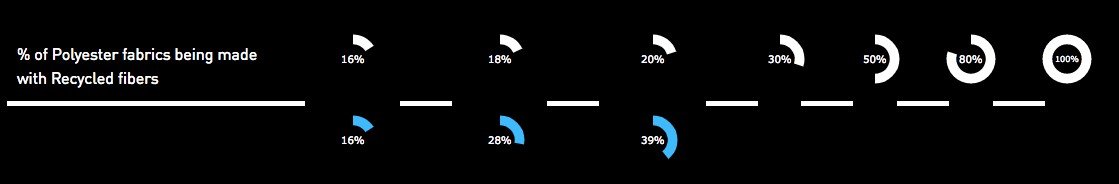

For Company, Production and Product, they have created checklists covering processes specific to these three pillars. Each criteria is matched by an amount of progress as a percentage of 100%, noted down at the end of each calendar year. The simple layout and granular definition of each category is especially clear, presenting a visualisation that’s legible to the averge consumer.

Here are some highlights:

What do you think? Should companies develop their own goals and select their own metrics, or should these be spread across multiple brand to educate the consumer more effectively? Email comments to will@zafiri.com.